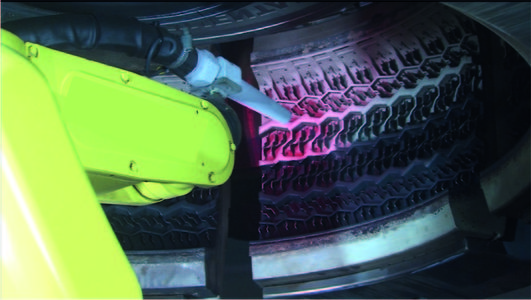

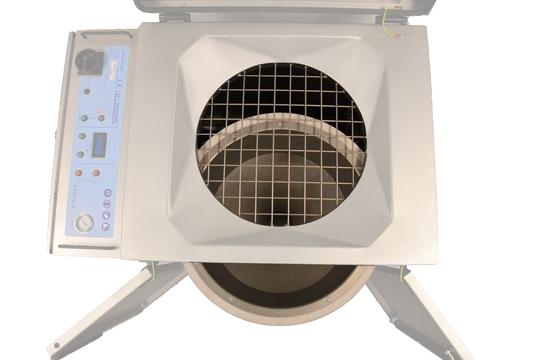

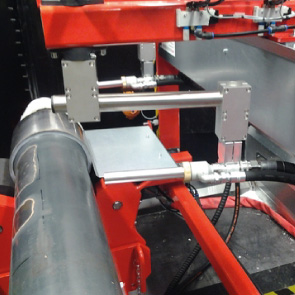

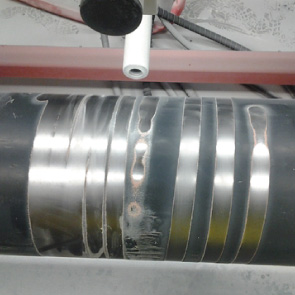

Dry Ice UK are The Dry Ice Cleaning Specialists – providing dry ice blast cleaning services throughout the UK.

We have consistently delivered dynamic and cost effective dry ice cleaning solutions to our customers for over 20 years. Whatever your requirements may be, Dry Ice UK has the people, equipment and expertise to meet all of your requirements.